Last Updated on July 17, 2023

What would life look like without fresh fruit, frozen meals, or ice cream? How would it feel if you had to go to the grocery store every day to buy fresh food? In just 150 years, refrigeration made it possible to keep food, medicine, and ourselves cool and fresh in any climate or season.

As an HVAC-R contractor, you know about the trials and tribulations of the refrigeration industry firsthand. But have you ever wondered how the refrigeration industry came to be? Are you curious about the current state of the industry today or whether the future of the industry looks bright? Do you know the best way to address industry challenges to stay ahead of your competitors? We’re covering all that and more “cool” refrigeration facts in this article.

The Invention of Artificial Refrigeration

Did you know that refrigeration is not a new industry? Refrigeration has actually been around since ancient times. Before we take a look at the refrigeration industry today, we thought it would be interesting to take a look back at the history of refrigeration to help us appreciate how far the industry has come.

The invention of refrigeration can be traced back to ancient history. In China, ice was harvested in the mountains and stored in isolated containers. Hebrews, Greeks, and Romans kept large amounts of snow in underground storage pits. The Romans are known to have eaten a lot of fresh ice cream from the mountains. Ancient Egyptians cooled water with the use of the night’s cool air.

Cool Fact: Emperor Nero, who lived from 37 to 68 AD, is said to have set up his own chain of runners between the capital Rome and the Albanian Berger to get fresh ice cream consistently.

In the Middle Ages, instead of cooling water at night, people rotated long-necked bottles in water in which saltpeter was dissolved. This method produced very low temperatures and even ice, but due to complexity, iced drinks and liquors were reserved for the rich. The rest of the people preserved and stored their food — especially milk and butter — in cellars, outdoor window boxes, or even underwater. But even these methods could not prevent rapid spoilage of perishable food, since pasteurization was not yet known and foodborne illness and poisoning, due to bacteria, was common.

The diet was the main force that powered the evolution of refrigeration. In old days, the North American diet consisted mainly of bread and salted meats. The diet reform between 1830 and the Civil War resulted in consumer demand for fresh milk, meat, fish, fruits, and vegetables. As cities grew, so did the distance between the sources of fresh food and consumers.

Natural ice supply became a booming industry in the early 1900s. For example, in 1907, 14-15 million tons of ice were consumed, nearly triple the amount in 1880. But natural ice became polluted because of sewage dumping. Refrigeration technology allowed for the mechanical manufacturing of ice, which led to mechanical refrigeration as we know it today.

Cool fact: Commercial refrigeration was first adopted by breweries in the 1870s.

How Refrigeration Has Grown to Become the Most Essential Food Storage Technique

Diet and food consumption transformed with the onset of refrigeration. Meat curing became a year-round activity because animals could be brought to market at any time, not just in winter. As a result, raw meat quality improved.

Refrigerated railroad car design was patented by J.B. Sutherland of Detroit, Michigan in 1867. These cars created regional food produce specialization. Think Georgia peaches, California grapes, pears, plums, and citrus, Washington and Oregon apples, pears, cherries, and raspberries, and of course, Florida citrus. The fresh foods markets helped to create healthier diets of meat, poultry, produce, eggs, butter, milk, cheese, and seafood. But it wasn’t until 1949 that a refrigeration system made its way into the trucking industry by way of a roof-mounted cooling device, patented by Fred Jones.

Cool Fact: Albert Einstein and Leó Szilárd patented the “Einstein refrigerator.” The new design had no moving parts and operated at constant pressure using only a heat source.

Sugar mills, confectioneries, chocolate factories, bakeries, tea companies — all food industry niches found that refrigeration helped their business. But other industries benefited from mechanically produced cold temperatures as well. In metalworking, for example, refrigeration was used to help temper cutlery and tools. Textile mills used refrigeration in bleaching and dyeing. Oil refineries and manufacturers of paper, drugs, soap, glue, perfume, and photographic materials — many industries found refrigeration a boost to their business. Fur and woolen goods storage could beat the moths by using refrigerated warehouses. And there was even a morbid application of refrigeration— preserving human bodies in the morgue.

When the Refrigeration Moved to Homes

Even despite the massive adoption of industrial refrigeration, households continued to rely on ice wagons that delivered ice when customers displayed an “Ice Today” sign in their windows. Ice was stored in iceboxes made of wood and lined with tin or zinc, which were further insulated with sawdust or seaweed. Water pans had to be emptied daily. Not an ideal solution!

It all changed in the 1920s when the first electric refrigerator for domestic use was invented by American inventor Fred W. Wolf. However, refrigerators didn’t become a common household feature until the 1940s. One of the main concerns was safety. In early models, the leakage of toxic gases had caused several fatal accidents. Scientists discovered a less dangerous method of refrigeration, Freon, which became the standard for almost all domestic refrigerators. The refrigeration market started to expand.

Cool Fact: The first refrigerator was called the Domelre, or the DOMestic ELectric REfrigerator.

Soon enough, by the mid-1950s, as much as 90% of American homes had their own refrigerators. The old-fashioned icebox survived and even evolved into a freezer chamber that can be found in most refrigerator models.

The Refrigeration Industry Today

It’s safe to say that the refrigeration industry looks a lot different today than it did back in ancient times or even in the 1950s! As those in the refrigeration industry are well aware, refrigeration today goes far beyond keeping food cold. In addition to the food industry, refrigeration also plays an important role in healthcare, energy, and the environment. This has led refrigeration to become much more complex, requiring highly specialized contractors and complex projects with many moving parts.

The refrigeration industry has also grown significantly. Here are some important statistics that provide an overview of the industry today:

- Roughly 3 billion refrigeration, AC, and heat pumping systems are currently in operation across the globe, including 1.5 billion domestic refrigerators (IIR).

- An estimated 12 million people are currently employed in the refrigeration industry (IIR).

- In 2019, the commercial refrigeration market size was valued at $28.19 billion. This number is projected to reach $35.35 by 2027 (Allied Market Research).

- In addition to 1.5 billion home refrigerators, there are 90 million commercial refrigeration systems and 47 million beverage coolers and refrigerated vending machines, all of which are growing significantly, with an average CAGR of over 5% (Carel).

The Most Significant Restraints for the Refrigeration Market

Even though the refrigeration industry is expected to grow, the industry is facing more challenges than ever before which can make it increasingly difficult for businesses to succeed. We’ll discuss some of the most common challenges in the following sections.

Lack of Proper Maintenance

As the number of refrigerators and their technical complexity continues to grow, the breakdown of air conditioning and refrigeration equipment has become a greater restraint for industry professionals.

There are many causes of air conditioning and refrigeration equipment breakdowns, but all fall into two general categories — mechanical failure or electrical failure.

Cool Fact: Mechanical breakdowns have traditionally represented 30 percent to 40 percent of all failures, while electrical breakdowns represent about 60 percent to 70 percent of total equipment losses. This category includes several causes such as lightning, voltage spikes, and a variety of “line disturbances.”

Murphy’s Law says that breakdowns are more likely to occur at night or on a weekend when repair service comes at a premium.

New Energy Efficiency & Environmental Targets

As home refrigerators became more common, the focus turned to refrigerators that use less energy and the elimination of chlorofluorocarbons in refrigeration sealed systems. In the 1970s, freon was banned, along with other greenhouse gases, due to evidence that they damage the Earth’s ozone layer and contribute to global warming.

Cool Fact: In 1994, many governments globally banned the use of R-22, the main component in freon, due to its damage to the ozone layer. Since the 1990s, the less harmful cooling agent has been used in older systems.

Refrigeration, including air conditioning, represents 15% of the global consumption of electricity. Refrigeration issues are linked with electricity issues, including global warming due to CO2 emissions since electricity production is still very dependent on fossil fuels. New sources of energy have higher costs, which means that the price of electricity will remain high. However, refrigeration can drive up new sources of energy such as solar and liquefied gases.

Many governments across the world are also making an effort to reduce hydrofluorocarbon (HFC) emissions. These synthetic greenhouse gases are mainly used in refrigeration and air conditioning equipment. To replace HFCs, more environmentally friendly synthetic and natural refrigerants are being used. The problem is that these refrigerants are potentially more dangerous to technicians which has created a demand for a skilled workforce with adequate safety training and knowledge of how to mitigate risks.

Lack of Skilled Technicians

Another challenge faced by the refrigeration industry is a shortage of skilled technicians. There are a number of reasons for this shortage, including an aging workforce, competition from other businesses in the industry, and the considerable amount of time required to achieve the necessary qualifications.

A lack of adequately qualified technicians not only poses safety issues but also affects customer satisfaction. If your technicians make mistakes or are unable to complete their jobs, this will negatively affect field service management metrics such as your first-time fix rate which in turn affects your customer retention.

Growth Opportunities for the Refrigeration Industry

Technology is not the only vector of growth for refrigerators, freezers, or air-conditioning systems everywhere–at home, in restaurants, or in industrial plants. In fact, industrial refrigeration units are widely used across many industrial sectors, such as food processing, cold storage, pharmaceutical, petrochemical, and liquified natural gas (LNG) liquefaction.

Cool Fact: The global industrial refrigeration market grew at a CAGR of around 6% during 2014-2019.

The fundamental changes brought upon the COVID-19 pandemic highlighted the importance of cooling devices of all sizes and applications.

The Rise in Home Delivery and Home Cooking

The first refrigerator 100 years ago changed the way people eat. Due to changing lifestyles, dietary patterns, and global lockdowns during the pandemic, consumers rely on packed, processed, and frozen ready-to-eat food items. But with the onset of a pandemic, consumer habits have changed.

Cool Fact: Deliveries of stand-alone freezers to retailers increased 40% during the first half of 2020.

Thanks to advances in refrigerating technologies, stores promote year-round availability so that we can eat bananas and strawberries at any time of the year. And with the onset of lockdowns globally, the online food, beverages, and grocery market has seen explosive growth. For example, food and grocery delivery services have reported a year-over-year increase of 500%in April 2020, according to the study. And as 2020 progressed (and much of the economy regressed), in-person dining was replaced with stay-at-home orders. Same-day or next-day services became a norm for groceries or prepared meal deliveries.

Cool Fact: The average storage capacity of a large grocery store is only one day’s worth of fresh products.

To meet the increased demand in home food delivery, with lockdown pressure piling up, the cold chain infrastructure has been improved. Among the recent innovations are natural refrigerant-based systems and internet of things (IoT) enabled monitoring systems.

And the refrigeration industry shows no signs of slowing down with adopting the latest technology. Even as mobility recovers and the world regains access to brick-and-mortar shopping, interest in delivery services will remain the same or higher, according to the data-based study. Just as the way we work will never be the same again, shopping for groceries will not be the same, either. Refrigerators and cold chain logistics will keep evolving. But the pandemic revealed another refrigeration industry’s opportunity for growth.

With people staying home more or having more people home than usual, appliances such as refrigerators are stressed and need servicing or upgrading. In addition to that, many people are remodeling to accommodate remote work and learning.

Instead of travels and shopping, people are reinvesting in their homes and focusing on healthier living and energy efficiency. That includes upgrading and maintaining kitchens, to make them energy-efficient and more resilient, reliable and breakage-proof.

Cool Fact: Demand for refrigerators has increased about 50% since April 2020, research shows.

Another reason for upgrading, despite long waiting lists, is that refrigerators are becoming smarter, too. The Internet of Things connected home appliances and eCommerce. LG launched the world’s first connected refrigerator, and Samsung released models with Wi-Fi and cameras that help keep track of when food is about to become spoiled.

Refrigerators to the Rescue from COVID-19?

With multiple COVID-19 vaccines being administered globally, there is hope that the world will gain the upper hand on the pandemic. The HVAC industry plays a key role. Here’s why.

Vaccines are biological products that can lose their effectiveness if they are not kept within a narrow temperature range. Fridges that are required to keep some of the vaccines at their required ultra-low temperatures are key to the success of the vaccination efforts across the globe. Pfizer and BioNTech demonstrated the stability of their COVID-19 vaccine when stored at -25°C to -15°C (-13°F to 5°F). These temperatures are commonly found in pharmaceutical freezers and refrigerators. The cooling technology is ready to make the world a safer place, again.

Cool Fact: Vaccine vials can be stored at -25°C to -15°C (-13°F to 5°F) for a total of two weeks as an alternative or complement to storage in an ultra-low temperature freezer, says the announcement.

In addition to the cooling technology, an adequate cold chain will be required to distribute vaccines to up to 5.5 billion people which is up to 70% of the world’s population, noted a new study from the University of Birmingham, United Kingdom. In particular, developing countries often lack “seamless, fully integrated functioning cold chains,” the report noted.

That’s when the Cooling as a Service (CaaS) model emerged. The servitization model was easily applied to the cooling industry, research notes, aligning the interests of business and the people who benefit from improved health care access. The transformation of the cold chain — the foundation of vaccination efforts globally — is just the beginning.

Software Advancements

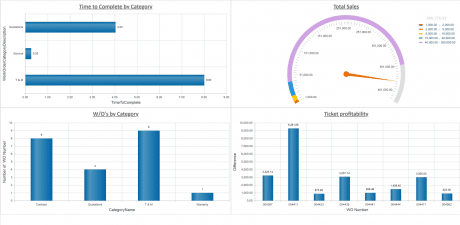

When faced with industry challenges (and even growth opportunities) it becomes increasingly important to lean on software solutions to help your business keep up. Construction & Service management software has come a long way over the years, effectively helping companies across the globe increase efficiency, cut costs, take on more projects, improve customer satisfaction, and much more.

Is your company struggling to keep up with maintenance requests? Service management software with service contract features, including preventative maintenance, could help you manage the complex world of planned maintenance agreements. With a software solution like Jonas, you’ll be able to empower your customers to create their own work orders and tickets. You’ll also have the option to bill customers either on a set schedule or for individual services, and bill your repair work against that contract.

Is your company struggling with a lack of skilled technicians? Software with dispatch scheduling features will help you make sure that the right technician with the necessary qualifications shows up for each job.

What about dealing with increased workloads due to industry growth? Construction & Service software can help you cut out unnecessary work, double entries, and even trips back and forth to the office so your employees can increase productivity and stay ahead of the competition

The Future of the Refrigeration Industry

The future of the refrigeration industry looks bright. Enjoying the spotlight as the main pillar of the vaccination global campaign, the refrigeration industry is reshaping the way we shop and cook. Among the main directions are:

- The low-temperature transport and storage will continue to evolve, so as to prevent bacterial growth. Currently, the lack of an efficient cold chain causes food wastage that, according to the International Institute of Refrigeration, accounts for 20% of global production. By making reliable refrigeration affordable and accessible, cold chain logistics will make a great step towards ensuring the safety of foods and medicines for the poorest countries.

- As the world’s population increases, the need for a worldwide cold chain to preserve the food supply will be crucial.

- Just as the post-COVID workplace will never be the same, so our shopping habits will have changed for good. In addition to the reliance on home delivery, the increase in female employment in emerging countries will lead to a significant rise in the consumption of frozen or ready-to-eat foods.

- The energy efficiency of refrigerators will continue to rise. With the invention of inverter-controlled compressors with brushless motors which modulate rotation speed (from 15-25% to 100%), power consumption is typically reduced by 20%-25%, with obvious environmental and economic benefits.

Automation and internet of things (IoT) technologies will increasingly play roles in the growth of the HVAC industry and so will the technologies that support this growth. It’s time to make environmentally friendly and financially viable refrigeration systems prosper with HVAC-focused service management software.

After all, commercial refrigeration systems can — and should — be in good working condition for decades. As we adapt to the profound changes that are shaping the industry, you need to make the informed decisions to maximize your technology investments.

Jonas Construction Software is the best construction & service management software for HVAC-R contractors. We’ve proudly helped many businesses in the HVAC-R industry improve their efficiency and profitability with our fully-integrated, purpose-built software. Contact us to find out more about how you can build a more profitable operation with Jonas.