Last Updated on July 17, 2023

Feb 01, 2017

Harrell-Fish Inc. is a mechanical contracting and service firm specializing in the construction, industrial, health care, commercial, food service, residential, and energy industries. They perform and excel in all areas including plan and spec work, design/build, construction management, and full 24-hour emergency service and maintenance.

This interview with Harrell-Fish CEO Dave Conner discusses their journey from an outdated software system, to a more modern and collaborative solution. Conner talks about their investment into mobile, and how Jonas Construction Software helped Harrell-Fish leverage automation and technology to take their business to the next level. Conner also outlines how Harrell-Fish strategically phased mobile technology into their day-to-day operations, giving everyone the opportunity to learn and grow together. With the goal of unifying the construction and service departments of their business, and with the hope of taking advantage of the latest technology, Jonas Construction Software was ultimately the right choice for Harrell-Fish.

Can you tell us about what your company does, and who your customers are?

Dave: Harrell-Fish is a mechanical contractor in south-central Indiana. We service all of Indiana with our construction and service activities. Our emphasis is on the service side, which includes HVAC and plumbing, with heavy focus on industrial work like piping, heating and cooling hydraulics. We also do work in the food service industry.

We’re in Bloomington, which is the home of Indiana University and a good portion of the work we do is with Indiana University. Then we do work for a lot of the industrial clients, such as General Motors, Cummins Engine, SALEO Industrial. We also do work in the bio-pharma world. Those are large industrial operations that just happen to be located in this area, but we also work on individual residences as well.

How many technicians do you have in the field at any given time?

Dave: We categorize our technicians three ways, 85 construction technicians, 30 commercial service technicians, and 14 residential technicians.

What were you guys using before Jonas and how long were you using that particular software?

Dave: Before Jonas we were using an outdated system called StarBuilder. I’ve been with the company now for about 9 years and they were already using StarBuilder prior to my arrival.

What challenges did you run into with StarBuilder on both the construction and service sides?

Dave: StarBuilder wasn’t as user-friendly as I hoped and it was burdensome to look up raw data. It was a much more complex process to find the data you wanted, and it was also difficult to extract that information.

On the construction side, it was just a little bit complex and difficult to use, easily getting lost in multiple screens. On the service side, it did not have an integrated service component. I refer to those often as interfacing programs, not fully-integrated like Jonas. So whenever you interfaced, you had some challenges.

What prompted you to make a switch, and look for a different software solution?

Dave: We started looking at technology migration probably about five years ago. So looking at it five years ago, we had a plan. The first started with mobile technology for our workers in the field. We knew we wanted to make that mobile connection. In addition, we had a desire to advance the professionalism of our services by putting data out in the field. This really motivated us to invest in another solution.

Why was having mobile capabilities such a priority for you at the time?

Dave: We wanted to go to mobile because it would provide technicians in the field better access to work history on equipment, client status and client relationship information. On the construction side, they’re out there working, and the construction foreman needed better job and project information. Not always just financial, but blueprints and drawings as well.

With mobile technology, our strategy was to slowly phase it in. We wanted to give them iPads and let them take pictures of project issues and incidents and let them communicate through mobile tools, instead of having an email or using digital cameras.

How did your workforce adapt to mobile?

Dave: It was challenging. Especially with a multi-generational workforce, we literally handed out iPads and some of the foremen would take them and say, “thank you,” and turn around and start showing us tools they could use. Others were unaware of how to operate it completely.

Where did Jonas come into play within this movement?

Dave: We started four or five years ago with a plan to really focus on field and mobile technology. When we did that, the first year and a half was based on just getting tools out there like the iPads so they would use them. We had loaded them up with apps and we did some creative things, creating forms that they can complete on an iPad and then send it in.

So after a year and a half of them becoming more advanced, we wanted an accounting system that could integrate with the mobile technology we were using. That’s what led us to our search, which resulted in us choosing Jonas.

Can you tell us more about the overall plan you had in place, starting with how you implemented mobile and how you ended up selecting Jonas?

Dave: Our plan was to introduce technology to people who hadn’t used it very much, and then continue to try to make it more and more a part of their daily activities. We equipped them with tools on iPads with safety activities and manuals. We immediately cut down on the need to carry 150 page notebooks with our safety manual in it and the OSHA requirements. With this in place, we wanted to pick a system that would integrate, or had a robust mobile technology capability.

Focusing specifically on Jonas, what has your experience with it been like?

Dave: The biggest challenge for us was dealing with change, but we had to focus a lot on the benefits that it was going to bring. We spent a lot of time preparing our team, and it went quite well. Because we did not come from an integrated system, we were able to slowly take aspects of our operation and slowly roll Jonas into that system.

To give you a very specific example, we did not previously write purchase orders electronically. Purchase orders were a manual process. Individuals would take a stack of pre-numbered purchase orders and hand write them. When they were completed, they photocopied or scanned them, then sent it either electronically or by mail. We would then put all purchase orders in a basket where our AP team would file them away, then match them up when invoices came in. It was very manual process. Currently with Jonas, we only create electronic purchase orders. Our first year using Jonas, we wrote 15,000 purchase orders inside the system. We went from a completely manual process to now completely electronic. I took that as a real home run.

Do you have examples of financial savings that Jonas has provided for your business?

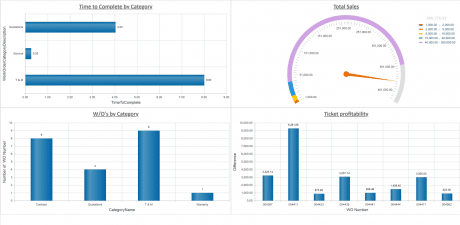

Dave: We are now able to turn billings around much quicker, because they can now go directly into the system, especially on work orders. We did 10,000 or so work orders last year. With Jonas, we have the ability to scroll through and comprehensively see what the purchase order was, what material was delivered, as well as other pertinent details. We are also able to locate discrepancies much quicker as well.

Do you have an example of how Jonas has helped with work order management?

Dave: We do a lot of what we call unbilled work orders. When I had a lot of jobs at one time, I’d manually go through and look at what jobs are out there that haven’t been billed, maybe because work orders haven’t been turned in. We were also not using a dispatch board previously, and all dispatching was done manually. We had multiple column worksheets that show where our guys were working.

Is there anything else that your business can now accomplish with Jonas?

Dave: Thanks to Jonas we did not need to hire additional administrative personnel in our service department that would have been necessary with our growth.

We also do a receiving log where we send out information to our bill personnel, what’s been received into the shop that day so they can see whether or not they should plan to come by and pick some material up for their project. Our time studies show that in the past, it took an hour a day to do that, to now about five minutes.

Our payroll process has also improved. In the past, we needed three individuals spending four hours once a week. With eTimesheets, we are confident that the collective 12 hours that were spent, can be cut down to one hour.

In terms of billing cycles, how has that improved with Jonas?

Dave: Compared to our previous software, we can get information in much quicker, which has reduced our billing cycles by about 10 to 15 days. The service side has also improved by about 5 to 10 days. Both processes have cut our billing cycles in half as compared to our previous software.

Is there anything you wish to add about Jonas?

One of the other positives about Jonas is – and this is key to us – they’ve demonstrated a constant improvement of the process. With our previous system, there was very little change and improvement. This may be why many people liked the software, but change and advancement is necessary.

Another thing I see from Jonas that I like is an attitude of refinement versus defense. I appreciate that about Jonas. They seem to take input and are constantly putting money back into the development of a better product.